At first look, surgical scissors just look like any common scissors we use for cutting, but in surgeries they have a crucial role. During procedures, surgeons use these scissors to cut biological structures such as tissues, organs, and also other non-biological materials like stitching materials, threads, bandages and strips.

It’s important to know these nuances, it helps to choose the right surgical scissor and significantly improves the outcomes of a surgical procedure and directly impacts the patient’s safety.

Our product range includes an extensive variety of these indispensable tools, made in high-quality stainless steel. We offer a comprehensive assortment of surgical scissors, including but not limited to the scissors mentioned here.

High-quality surgical scissors are more than just tools; they are extensions of a surgeon’s hands, necessary to perform life-saving procedures.

We are happy that we can deliver fast shipping and an extensive product range so surgeons can have the right tools at the right time.

Variety of Types and Designs:

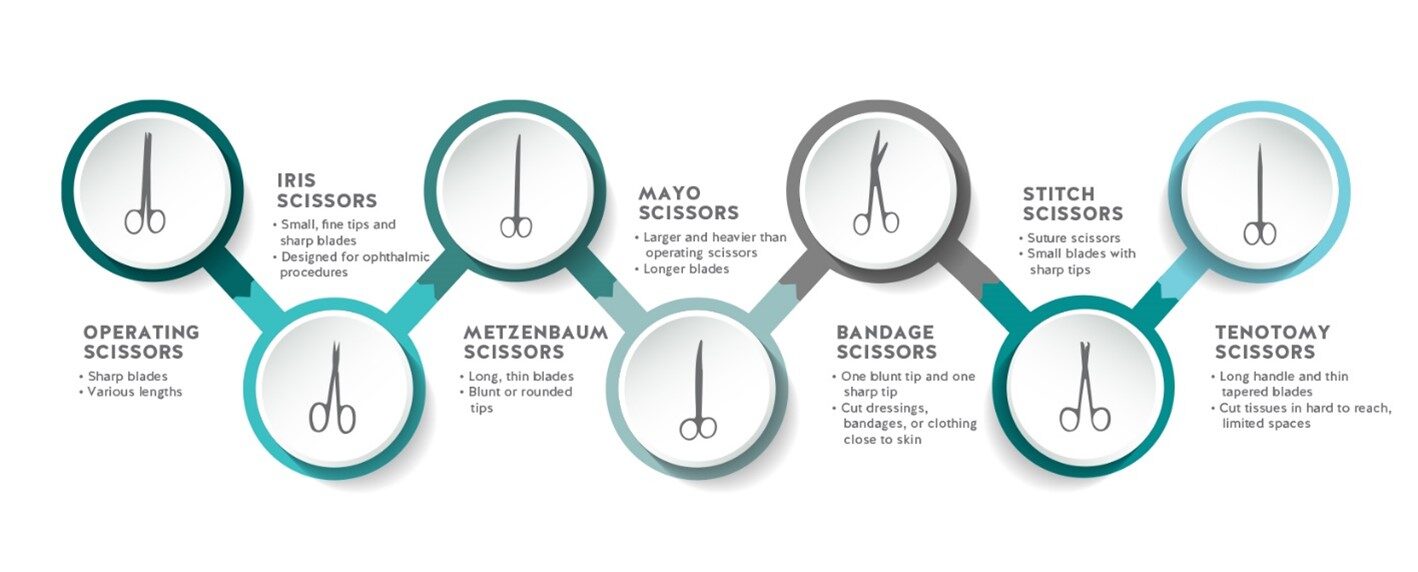

There are several types of surgical scissors, each designed for specific purposes. Here are some of the most common:

Operating scissors: These are general-purpose scissors used for cutting through soft tissues, such as skin, muscle, and fascia.

Iris Scissors: These have small, delicate blades that are ideal for the precise cutting of fine tissues, such as those in ophthalmic and plastic surgeries.

Metzenbaum Scissors: These are longer and more slender than operating scissors and are used for delicate dissection and trimming of tissues, such as in neurosurgery and microsurgery.

Mayo Scissors: These have a longer, thicker blade than operating scissors and are used for cutting through tougher tissues, such as cartilage and fascia.

Bandage Scissors: These have a blunt tip and a curved blade and are used for cutting through bandages, dressings, and other materials without injuring the patient.

Stitch Scissors: These have a small, pointed tip and a sharp blade for cutting through sutures and removing stitches.

Tenotomy Scissors: These have a short, pointed blade and are used for cutting through tendons and ligaments.

Materials and Construction:

Surgical scissors are usually made from high-quality stainless steel. The material is durable and highly resistant to corrosion. Stainless steel is also marked by high tensile strength, which is essentially important for these scissors since they need to cut through delicate and tough tissues.

Moreover, stainless steel is a material that is not porous; hence, it allows easy cleaning and sterilization using an autoclave after surgeries.

Precision and Sharpness:

Surgical scissors have very sharp blades for precise and clean cuts which is important for delicate surgical procedures. Surgeons need this sharpness for a higher accuracy rate. Having sharp blades allows surgeons to reduce operating time, minimizing patient discomfort, and improving overall surgical outcomes.

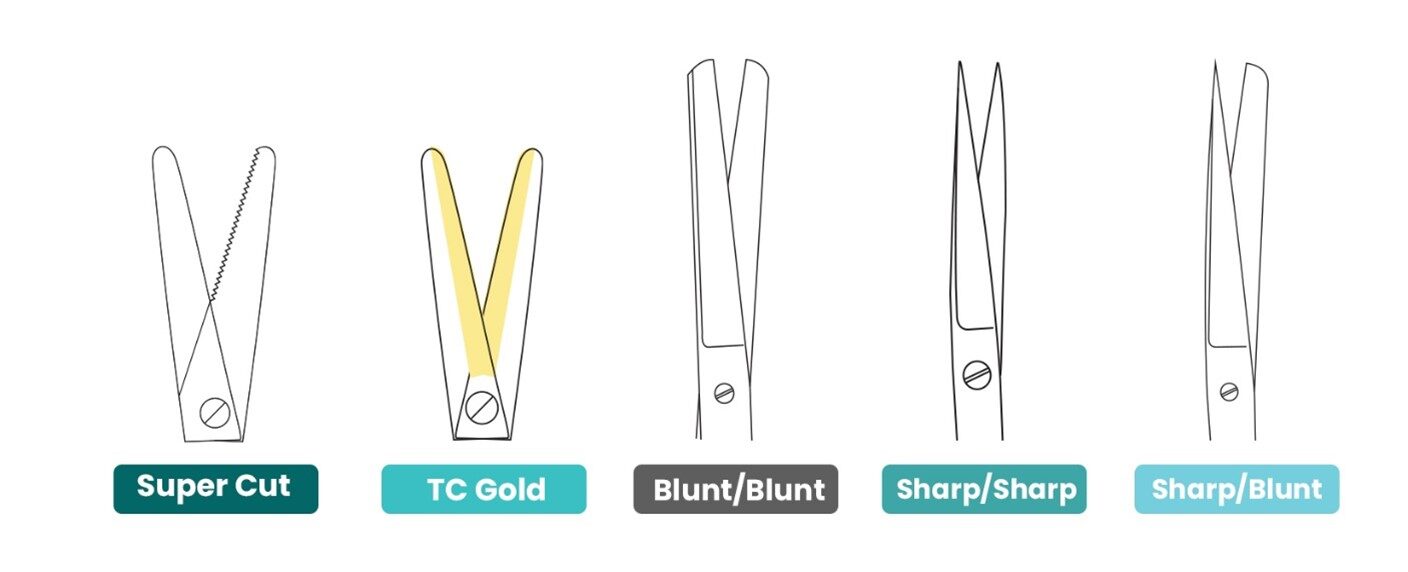

The tip of these scissors also have configurations tailored to the specific needs of surgeons. Some scissors have (Sharp/Sharp), (Sharp/Blunt) and (Blunt/Blunt) tip configurations, surgeons use them as per their own preferences. These specifications can be seen on the product page of each of the scissors that we offer.

Some scissors have micro-serrated blades, commonly referred to as Super-Cut. These micro serrations hold the tissues firmly and cut soft and heavy tissues efficiently. Their sharp edge gives a clean cut with minimal tissue damage.

Sterilization and Maintenance:

Taking good care of your surgical scissors will help them last longer and work better. Surgical scissors need to be clean and completely dry right after the surgical procedure. While cleaning, pay extra attention to the joints, hinges, and any parts where metal touches metal. These are the areas where rust appears if not cleaned properly, which leads to rapid bacterial growth.

Inspection:

Properly inspect the scissors for any damage, such as cracks, chips, or dull blades. Damaged or worn-out scissors should not be sterilized and immediately replaced with new ones as they could pose a risk to patients’ safety.

Packaging:

Cleaned surgical scissors must be properly packaged in a sterilization-approved wrapper or containers to protect them from recontamination during the sterilization process.

Autoclaving:

Place the packaged scissors in an autoclave and follow the manufacturer’s instructions for the appropriate temperature, pressure, and duration of the sterilization cycle.

Documentation:

A detailed record of the sterilization process should be maintained including the date, time, and parameters used during the sterilization process. This ensures traceability and compliance with regulatory requirements.

Importance in Surgical Practice:

To guarantee safe and effective surgical procedures, surgeons should always pick high-quality surgical scissors. These scissors offer consistent performance, durability, and precision. In the long term, you may save money and improve patient safety by investing in high-quality scissors built from excellent materials.

Let’s talk about your type of Surgical Scissors.